Relcalink®: cutting-edge carbodiimide crosslinkers

Contribute to lowering carbon emissions with Relcalink®, while maintaining the same performance as traditional crosslinkers.

Through the use of RelcaLink® carbodiimide crosslinkers, Stahl offers innovative solutions that enable customers to enhance the environmental profile of their products and processes, ultimately contributing to the reduction of scope 3 emissions.

Benefits

Low toxicity reduces labelling requirements

Improve chemical and scratch resistance

Quick and efficient processing: crosslinks at room temperature; no need for high temperatures

Outstanding adhesion to wide range of materials

Excellent pot-life: up to several weeks depending on pH

Swiss ordinance compliant for indirect food contact

Creating the future of crosslinking with Stahl’s Relcalink® range

RelcaLink® crosslinkers set a new standard, being the most sustainable, safe and easy-to-use option for high-performance crosslinking. Carbodiimides are defined as non-hazardous under GHS (Global Harmonized System), and most of Stahl portfolio is compliant for indirect food contact applications. Carbodiimides react at low temperature and offer extended pot-life, which make them easy-to-use to formulate high-performance inks, paints and coatings, from do-it-yourself to high end industrial applications.

Product name | Type | Solids (%) | Viscosity (cP) | Solvent system | VOC (%) | Label on product |

|---|---|---|---|---|---|---|

RelcaLink® 70 | Standard-Long pot-life | 40% | 25-300 | Water | 0 | No Label |

RelcaLink® 71 | Standard-Extended pot-life | 40% | 0-500 | Water | 0 | No Label |

RelcaLink® 72 | Standard-Long pot-life | 100% | 9,000 - 15,000 | - | 0 | No Label |

RelcaLink® 90 | Secondary reactive group | 100% | 15,000 - 20,000 | - | 0 | No Label |

Application markets

Application markets

|

|

How does Relcalink® work?

Download the brochure by filling out the download form and figure out how Relcalink® work.

Test to the best

Did you know that Stahl has several Centers of Excellence around the globe? We can help on the transition to more sustainable solutions through lab testings in our global Centers of Excellence. Click here to find a Stahl Center of Excellence in your region.

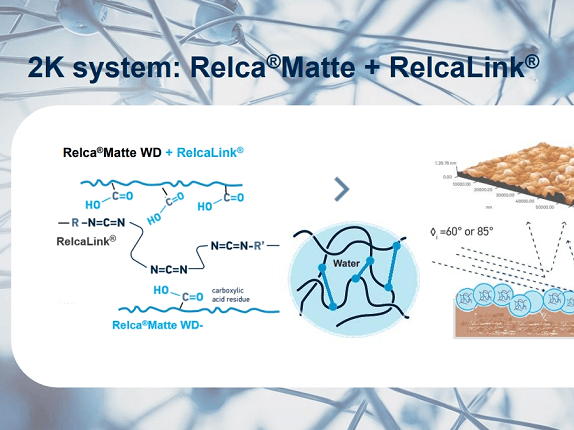

Webinar: New carboxylic-functional ultramatte binder for 2K systems with carbodiimide for high performance coatings

Low VOC & label free alternative

Optimised -COOH functionality

Chemical & mechanical resistances

Transparency & self-healing

Discover RelcaLink® HX-1: Hyperfunctional Polycarbodiimide Crosslinker

Extended pot-life

Non-hazardous labelling

Versatile applications

Best substitution of polyazirdines

Fast reactivity at room temperature

Good anti-staining properties

DOWNLOAD OUR WHITE PAPER

Polycarbodiimide crosslinkers:

A lower greenhouse gas emission solution

Improved chemical resistance

Reduced carbon emissions

Improved pot life

Frequently Asked Questions

Please get in touch and send us your question if it is not listed below.

Which RelcaLink® product should I choose for water-based systems?

- For water-based systems, choose RelcaLink® 70 or RelcaLink® 71, both offering 40% solids content and VOC-free formulations.

What's the best option for maximum pot life?

What makes RelcaLink® ideal for industrial wood coatings?

What affects pot life when using RelcaLink® crosslinkers?

Contact us