Stahl NuVera®: Leading the transition to renewable materials

Consumers increasingly expect products to be produced responsibly and with minimal environmental impact. One way for fashion, footwear, or upholstery manufacturers to do this is by replacing fossil fuel-based chemistry with renewable carbon-based materials. The Stahl NuVera® range of renewable carbon polyurethanes can help manufacturers do exactly that.

Stahl’s environmentally driven solutions are a key part of its strategic focus and go back many decades, from Stahl’s development of water-based polyurethanes in the late 1970s to the more recent introduction of its renewable carbon-based polyurethanes. Stahl’s commitment to minimizing impact always drives its product innovation.

The Stahl NuVera® product range can help manufacturers reduce their environmental impact without compromising on quality or performance. The introduction of this portfolio is in line with the company’s Responsible Chemistry Initiative, with which we commit to speed up the transition from fossil carbon to renewable carbon for all organic chemicals and materials. In the case of Stahl NuVera®, we do this by replacing petrochemicals with renewable resources (biomass, recycled materials, and CO2 captured).

Renewable carbon content and Life Cycle Assessment (LCA)

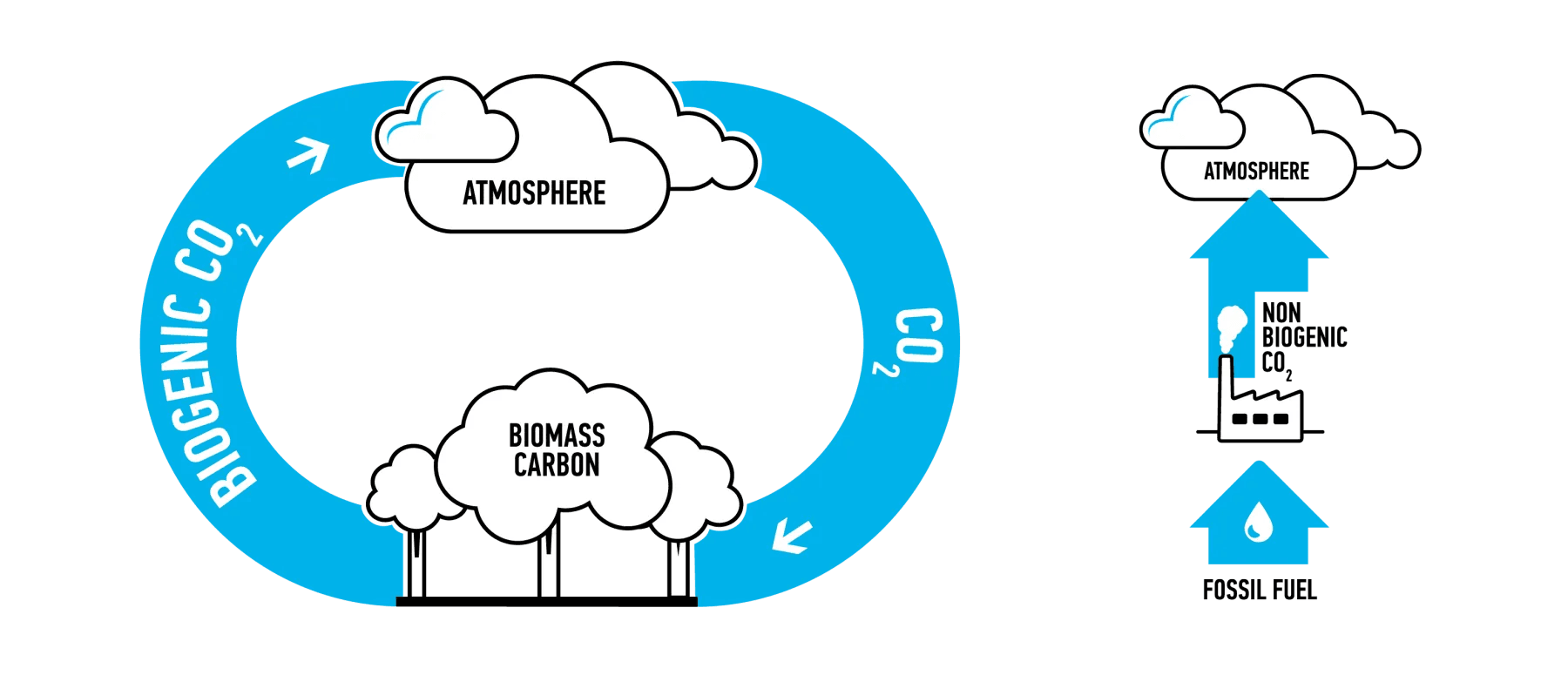

Biomass-based products are wholly or partially derived from materials of biological origin, like plants. As they grow, plants absorb CO2 from the atmosphere through photosynthesis and produce (hydrocarbon-) biomass. After harvesting, this biomass can be used as a raw material for biomass-based products, like Stahl NuVera®. The carbon absorbed during this process is known as biogenic carbon.

The uptake and emissions of biogenic CO2 are part of a short cycle and have net zero impact at the end of life. Burning fossil-based materials releases carbon that has been trapped in the ground for millions of years, resulting in net additional CO2 emission into the earth’s atmosphere, however, burning biomass emits C02 that was already part of the biogenic carbon cycle.

Several Stahl NuVera® coating components are biogenic CO2 sinks as they contain biomass-derived building blocks. Fossil fuel processing increases the total amount of carbon in the atmosphere, while biomass combustion returns carbon to the atmosphere that was already absorbed during the life of the plant. This is the fundamental advantage over using classic fossil-based alternatives.

At Stahl, we are committed to sharing the latest Product Carbon Footprint (PCF) data with our customers that is available for all NuVera® products.

Click here to learn more about Stahl's Life Cycle Assesment methodology, click here.

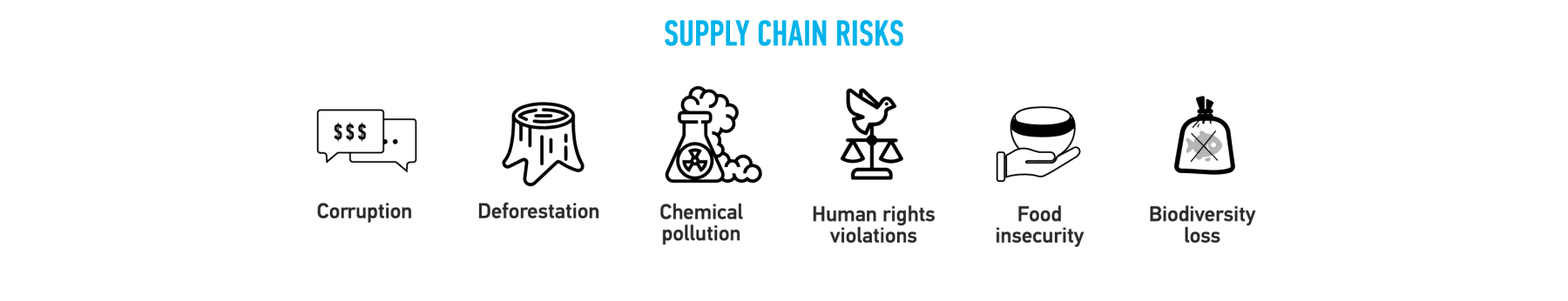

NuVera® Supply Chain Transparency

Today’s coatings industry relies on an interconnected web of global suppliers, intermediaries, and other stakeholders. These complex networks can potentially lead to supply chain “risk areas” — where a lack of oversight obscures the origins of specific products or raw materials. At Stahl, we’re committed to mitigating these risks and advocating for the highest environmental and ethical standards throughout our value chain. This ambition is especially relevant as we transition toward more renewable feedstocks, such as biomass.

This is why we are performing supply chain mapping for the renewable raw materials contained in NuVera® products.

Use of Mass Balance Feedstocks

Post-consumer and post-industrial recycle streams are becoming more easily available and allow for a much more favorable CO2 footprint than their virgin fossil alternatives. The availability of recycled-based raw materials or intermediates is rapidly increasing.

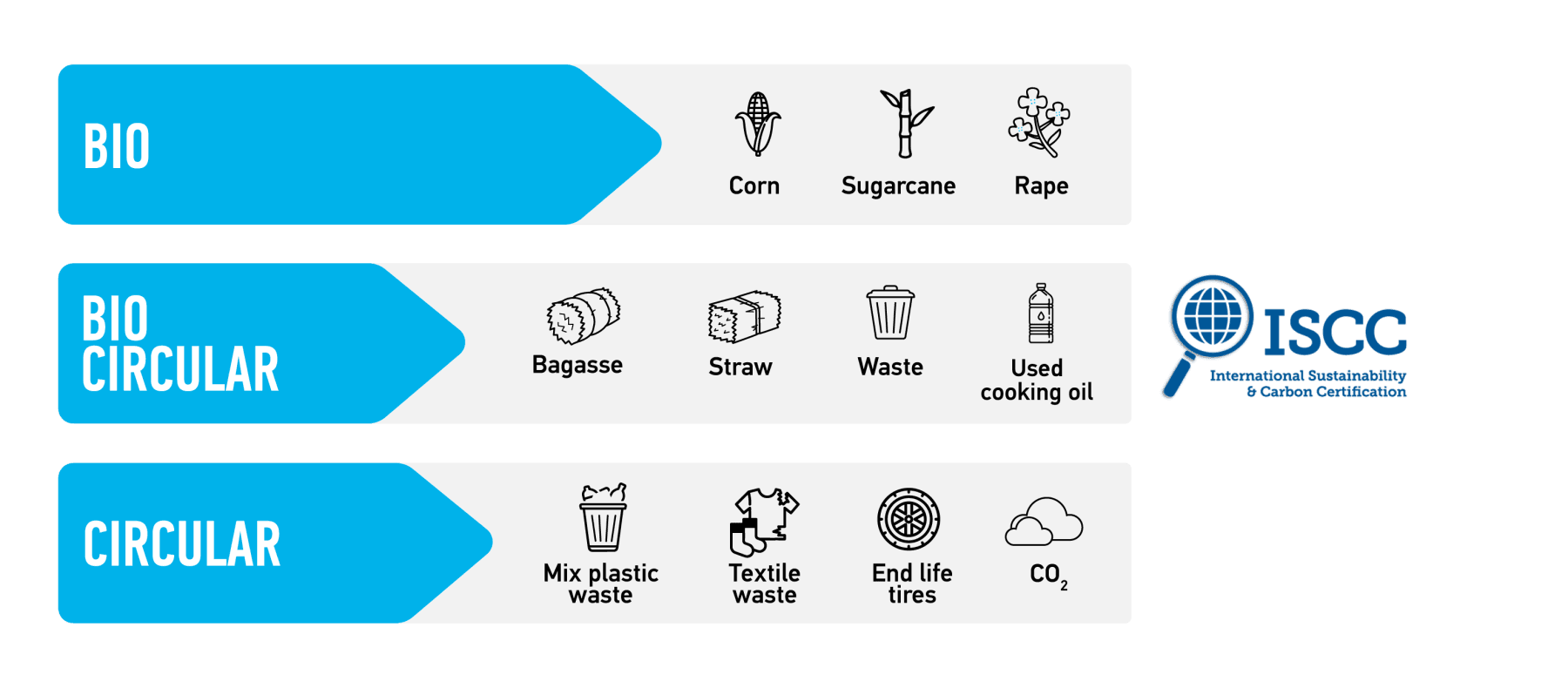

To support those environmental claims about the use of recycled materials inside consumer goods are justifiable and correct, a chain of custody certification system via The mass balance approach is set up by certification schemes such as ISCC PLUS. Chain of custody certifications require annual checks throughout the entire supply chain to certify the credibility of environmental claims made. This certification provides traceability throughout the supply chain and verification that the certified raw materials used at the product level meet high environmental and social standards.

The NuVera® MB family has been created to introduce the mass balance chain of custody model for circular and bio-circular raw materials. Due to the mixing of recycled hydrocarbon streams together with regular petrochemical feedstock, these mixes follow the standard petrochemical production process. Mass Balance certified products may substitute their conventional countertypes without the need for formula testing or performance loss.

ISCC PLUS raw material categories:

Our Stahl NuVera® Range

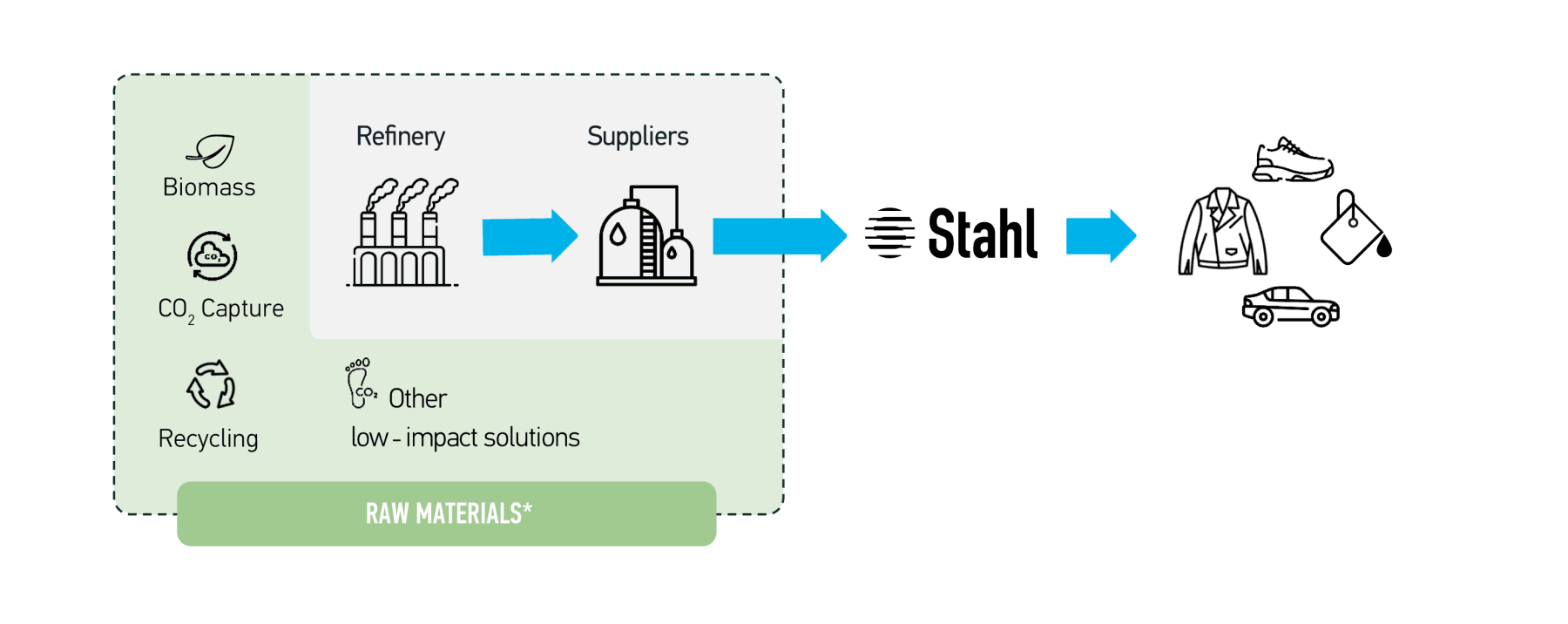

Stahl NuVera® renewable carbon-based products use (a combination of) different raw materials.

These raw materials can be either derived from biomass, captured CO2 or recycled materials, all these options can be used as feedstock to produce the chemical building blocks of our coatings.

Meanwhile our NuVera® range has grown to be a versatile mix of products. Products that are available in either acrylic dispersions, PU water-based dispersions (up to 50% solids) or 100% high solids PU pre-polymers.

Whether polyurethane or polyacrylic in nature, both families of products are readily available for coating and/or finishing of flexible or more rigid materials. As we continue to develop a wider range of product capabilities, we recommend you connect with your Stahl contact to discover all available options. Needless to say, the entire range of NuVera® products come with the above referenced details regarding supply chain transparency and carbon footprint declarations. In addition, all biomass based product offerings also come with ASTM D-6866 carbon isotope method of bio-based carbon content certification.

ZDHC MRSL Compliancy

The entire Stahl NuVera® renewable carbon-based product range comply with the latest standards and regulations, including the latest Zero Discharge of Hazardous Chemicals (ZDHC) Version 3.1 Manufacturing Restricted Substances List (MRSL).

Contact us