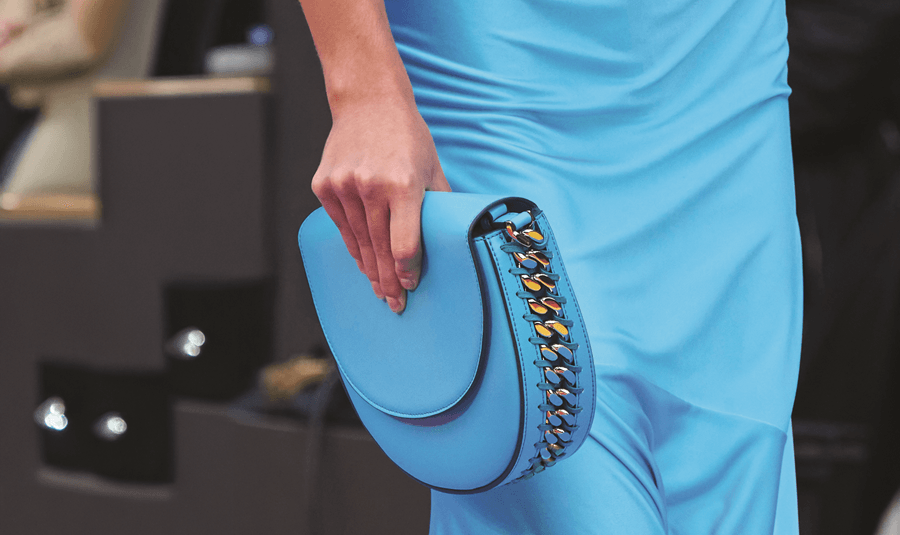

Premium Leather Design Collection | Spring Summer 2027

Discover our inspiring leather collections and design items based on different Pantone trend colors. Made with sustainable product solutions in leather finishing.

Stahl offers versatile leather finishing solutions that help manufacturers ensure safety and reduce their environmental impact. Our chemicals support a variety of needs – from leather upgrading to color finishing. And with our technicians close at hand, we can formulate custom finishing systems to your requirements.

Stahl’s leather finishing portfolio helps leather manufacturers achieve a range of high-quality finishes in a safe and responsible way. Our chemicals meet international safety and environmental requirements, including the Zero Discharge of Hazardous Chemicals (ZDHC) Manufacturing Restricted Substances List (MRSL). Many of our leather finishing solutions are included in our low-impact Stahl Neo® portfolio.

After the leather production process, the leather is treated with coatings and upgrading solutions to change, improve, or develop its appearance or characteristics. This process is called leather finishing. The first step is to apply upgrading solutions that cover grain defects, using stucco. Next, the basecoat – which forms the base for the leather design – is applied. Finally, the leathers are finished with a topcoat to support the manufacturer’s visual and physical specifications. The final coloring is also applied to the topcoat, which levels the color of the leather. With specific topcoats, you can also create matt or gloss surfaces.

We offer a variety of finishing solutions that support the production of multiple types of leather.

Discover our finishing solutions in the overview below:

Leather preparation

Leather enhancement

Leather protection

Color finishing

System solutions

Create high-performance bases, sealers, and topcoats with our leather preparation portfolio, which includes oils and waxes, auxiliaries, protein binders, dullers, fillers, or hand modifiers.

Stahl proudly introduces Syncros™, a novel generation of hyperfunctional carbodiimide crosslinkers designed to bring high performance and sustainability to leather finishing.

Stahl has been awarded the Platinum rating by EcoVadis for the fourth year in a row. It is a proud moment to be recognised by Ecovadis within the top 1% of over 150,000 companies assessed worldwide.

.jpg)

Waalwijk, the Netherlands, 25 January 2024 – Stahl, the world leader in speciality coatings and treatments for flexible substrates, has achieved Zero Discharge of Hazardous Chemicals (ZDHC) MRSL 3.1 Gateway certification for 2,151 products in its portfolio. This achievement underlines Stahl’s ongoing commitment to the ZDHC mission of achieving the highest standards for sustainable chemical management.

Discover the Stahl Design Studio

Discover our inspiring leather collections and design items based on different Pantone trend colors. Made with sustainable product solutions in leather finishing.

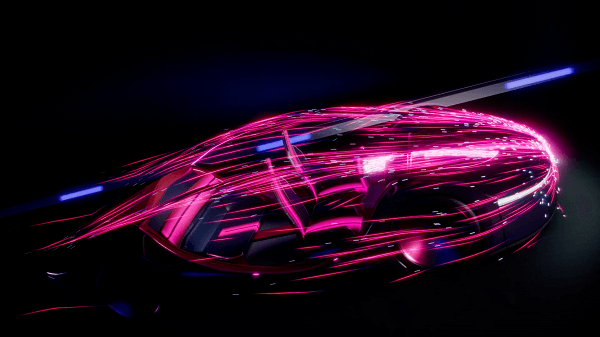

Stahl Design Studio® is your go-to partner for the newest trend research, latest insights and the best solutions for Automotive, Apparel & Accessories and interior design applications.

The automotive industry is evolving faster than ever, blending fashion-forward aesthetics, advanced coating technologies, and sustainability into every detail. Our Automotive 2026 Design Collection explores the trends shaping tomorrow’s interiors—where innovation meets style.