Advanced production with In Mold Coating Systems (IMC)

To improve the durability, haptics and looks of synthetics for car interiors or other applications, Stahl has developed effective In Mold Coating systems. These make it possible to integrate high-performance coating technology into your molding process, which reduces or eliminates VOC dispersion. With our IMC systems, you protect products against UV light, weathering and cleaning products, while you strengthen the flexibility and softness of the material.

Effective production with many possibilities

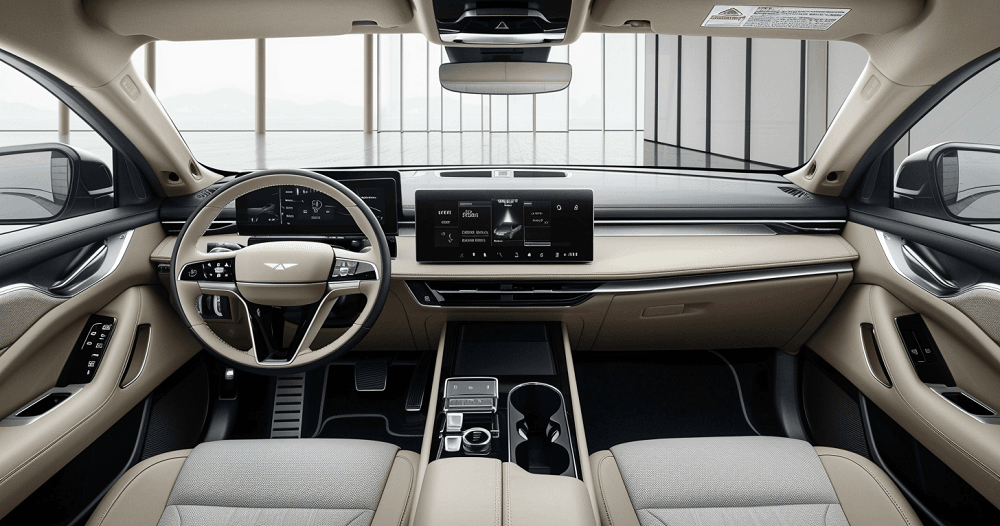

Dashboards, armrest consoles, door panels and steering wheels in cars need to be protected against deterioration by discoloration, weathering and cleaning products. Our aliphatic polycarbonate technology assures long-term durability. In addition, it is a more efficient and safer system with fewer processing steps, which could result in cost savings and a reduction in energy use. If you want to strengthen the chemical resistance even further, add one of our crosslinkers to enhance the coating properties. Whether you use closed or open molds, we provide coatings according to your color references. Even the combination of two colors in one process step and mold is possible.

IMC processing steps

Mold temperature of 40 - 85 ºC

Spray release agent

Spray IMC

Dry in 1 - 2 minutes (max. temp of 210 ºC)

Spray or inject aromatic material

Short reaction

De-mold

Key benefits of our In Mold Coating Systems

Our IMC systems meet the requirements of leading automotive brands. It provides a more pleasant touch compared to other common automotive systems, which is all down to the materials used. The system offers more design freedom and complex shapes are formed more easily. The technology that is used provides a lower density and a durable low gloss effect provided by our Polymatte® coating or other Stahl developments. No additional matting agents are needed for a result that doesn’t gloss up after aging. For interior decorative surfaces, multiple colors can be utilized easily.

Key Benefits

Long term durability

Pleasant touch

Homogeneous surface

Low gloss, also after ageing

Excellent color and heat stability

Close pores for easy cleaning

Excellent grain replication

Crosslinker strengthens chemical resistance

Low-VOC, NEP & NMP free