Water-based coagulation: a solvent-free solution for PU substrates

Stahl has developed PermUCell™ a new high-performance 100% water-based solution for PU-coated textiles that balances exceptional performance and high environmental safety standards.

Supporting a cleaner synthetics value chain

In recent years, we’ve seen a new wave of regulatory and market-driven initiatives to eliminate the use of dimethylformamide (DMF)1 in the production of synthetic articles.

These developments include new REACH restrictions on DMF introduced by the European Commission, which set significantly reduced worker‑exposure limits beginning in December 2023 under Annex XVII. Meanwhile, industry initiatives such as the ZDHC Roadmap to Zero programme continue to strengthen expectations around safer chemical use.

Together, these regulatory and voluntary frameworks are driving manufacturers toward safer, lower‑impact chemistries across textiles, leather, rubber, foam and related supply chains.

Innovating ahead of the curve

For several years, Stahl’s experts have been working proactively to help our partners adapt to this changing landscape – and comply with new regulatory and market requirements ahead of time.

In line with our commitment to responsible chemistry, Stahl maintains its own internal Restricted Substances List (RSL), to monitor hazardous substances that are under scrutiny from regulators and market actors. This allows us to stay ahead of regulatory changes and industry trends. It also catalyzes the development of alternative products that allow our customers to ensure full compliance, ahead of schedule.

Our R&D teams are constantly working to formulate new low-impact products and solutions that avoid the use of restricted substances completely. Of course, it’s essential to never compromise on quality and performance. That’s why Stahl’s application engineers at our global Centers of Excellence are able to precisely replicate the production processes employed at converters’ facilities to make synthetic articles.

This allows our development teams to create authentic product prototypes to validate the performance of our DMF-free solutions – ensuring they provide the high-quality, high-performance results that the market expects, exceeding the required standards.

Framis Italia Joining forces for water-based innovation in fashion

Framis Italia creates innovative, sustainable and customisable thermoadhesive solutions for the fashion industry, including embellishments, films and tapes. They're on a mission to lead breakthrough innovation in fashion that contributes to a healthier industry and planet.

They wanted to move away from dimethylformamide (DMFa)-based coatings towards a more sustainable and innovative water-based solution, and Stahl was their partner of choice.

Stahl’s next generation water-based technologies

Through extensive research and development, Stahl can offer a full spectrum of DMF-free synthetic coating solutions to support customers at different stages of the production process. The solutions we offer range from pre-skin to skin and adhesive layers, and from basecoats to topcoat finishes.

For customers working with water-based systems, Stahl provides the PermUCell™, PermaQure and NuVera® ranges of water-based dispersions, high solids resins, coatings, binders, and ready-to-use formulated lacquers.

The NuVera® product range offers coatings based on a variety of renewable chemistry feedstocks, such as biomass, captured carbon, and recycled waste materials.

Meanwhile, our PermUCell™ range builds on Stahl’s next‑generation water‑based technology, offering a truly DMF‑free alternative to conventional solvent‑based systems.

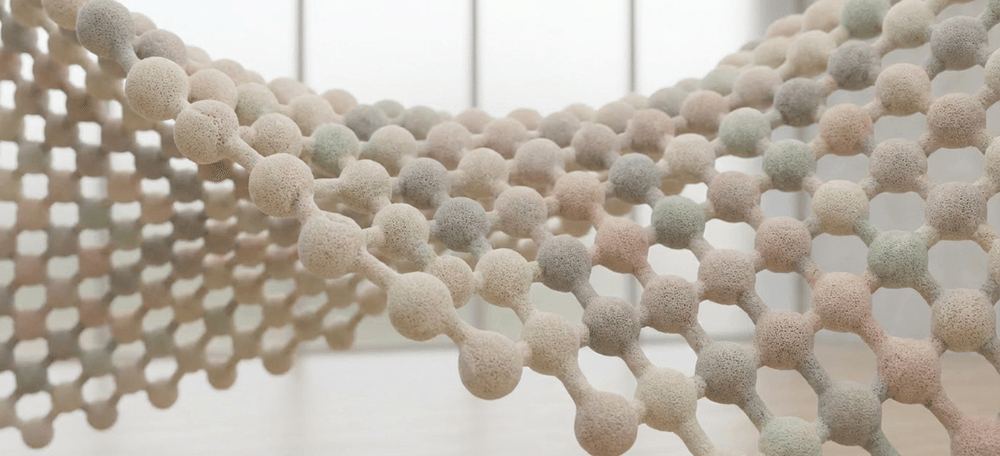

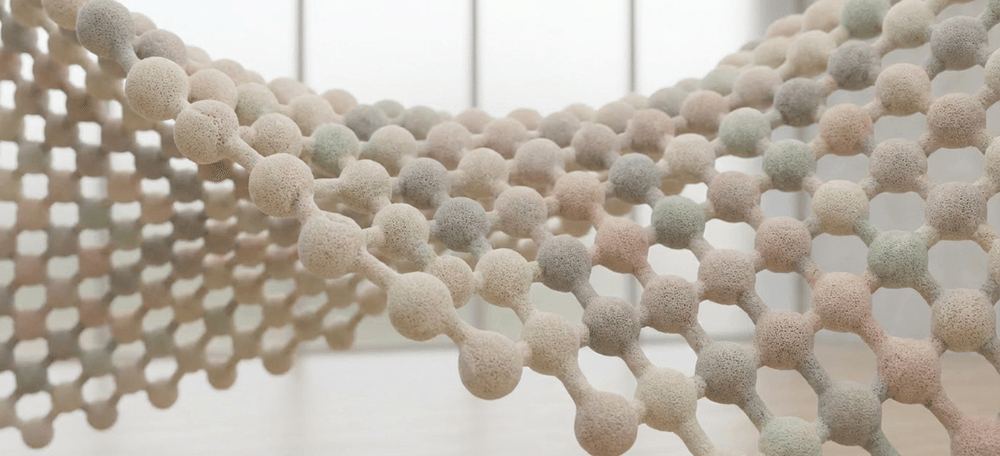

Developed as part of Stahl’s broader portfolio of water‑borne polyurethane innovations, PermUCell™ RC-2234 enables manufacturers to create high‑quality coated base layers with the same porous, breathable, soft and flexible characteristics traditionally achieved through DMF coagulation, while significantly reducing environmental and worker‑exposure risks.

By replacing solvent-based wet coagulation with a water‑based process, PermUCell™ solutions provide a low‑impact pathway for producing synthetic materials across apparel, footwear, accessories and upholstery applications delivering superior performance to DMF-based processes while eliminating solvent use entirely.

Ready to be part of a DMF-free future?

Watch our webinar below or download our new brochure to discover more about the synthetic coating solutions on offer at Stahl. Also feel free to read more about DMF in our blog. Find more about all our performance coatings solutions here.

1 NOTE: Dimethylformamide is also known as N,N-dimethylformamide or DMF(A).

What’s covered in this webinar:

Why coagulation matters in synthetic material production

Limitations of solvent-based methods

Stahl’s water-based coagulation explained

Compliance and environmental benefits (ZDHC-MRSL & REACH)

And more

Stahl has developed PermUCell™ a new high-performance 100% water-based solution for PU-coated textiles that balances exceptional performance and high environmental safety standards.

Create smooth and thick layers of coating with the PermaQure® reactive high solids. A solvent-free polyurethane coating for maximum effect and coverage, free of hazardous substances.

Renewable carbon-based polyurethanes, acrylics and polymatte coatings enabling coating and ink formulators to combine high performance with an improved environmental footprint.